Carbon lattice wheelchair cushions combine digitally engineered comfort, advanced pressure distribution, and long-term performance. These cushions surpass traditional materials such as foam, gel, or air by delivering stable support, optimized breathability, and enhanced tissue protection for users of manual and powered wheelchairs.

This advanced solution not only improves daily comfort but also mitigates risks associated with prolonged sitting, including pressure ulcers and joint fatigue, a significant consideration given ongoing global growth in demand for advanced wheelchair seating solutions.

Why Choose Carbon Lattice for Wheelchair Cushions

Carbon lattice wheelchair cushions are engineered to evenly distribute pressure and absorb shocks in a controlled manner. Key benefits include:

Even pressure distribution to reduce skin stress and hotspots, a critical factor in cushion performance and pressure ulcer prevention.

Controlled impact absorption to cushion repetitive forces, especially over uneven surfaces.

Optimized microclimate through natural airflow channels in the lattice, reducing heat and moisture buildup.

Superior durability, maintaining consistent performance long after traditional foam or gel materials degrade.

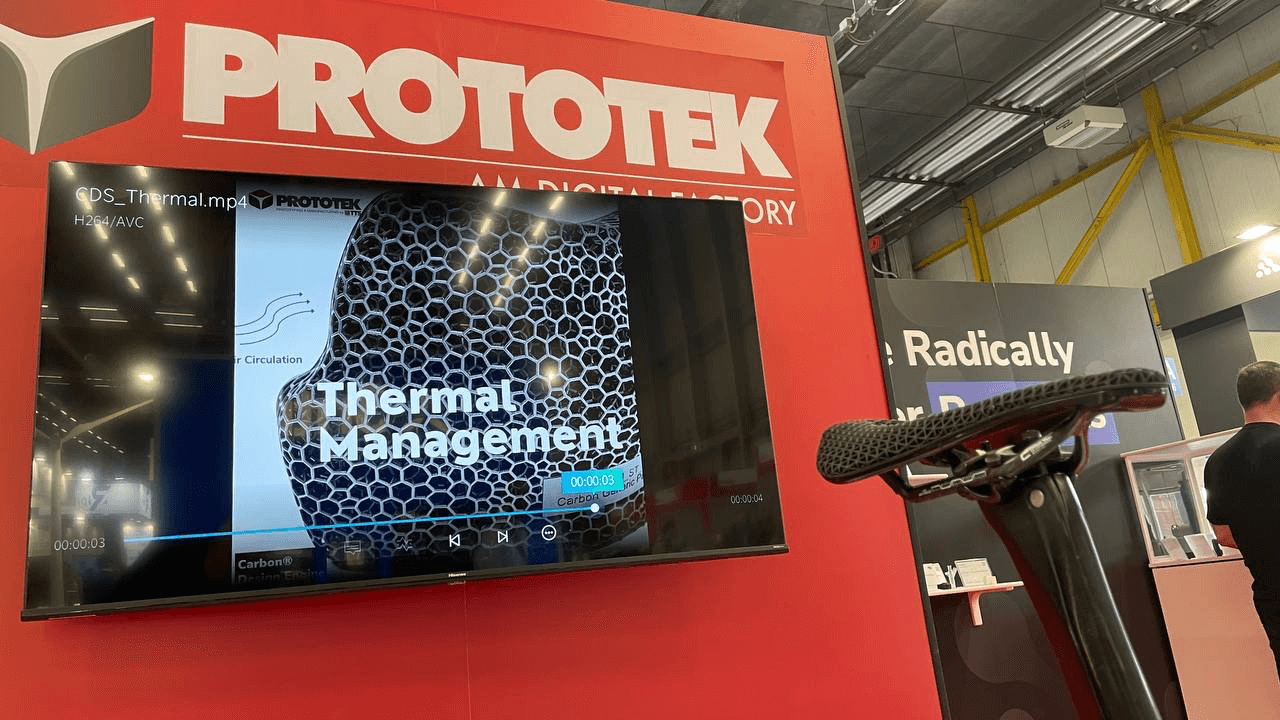

The advanced Carbon DLS™ (Digital Light Synthesis™) technology enables designers to balance comfort and prevention by tailoring geometric lattices to individual needs, enhancing both clinical and lifestyle applications.

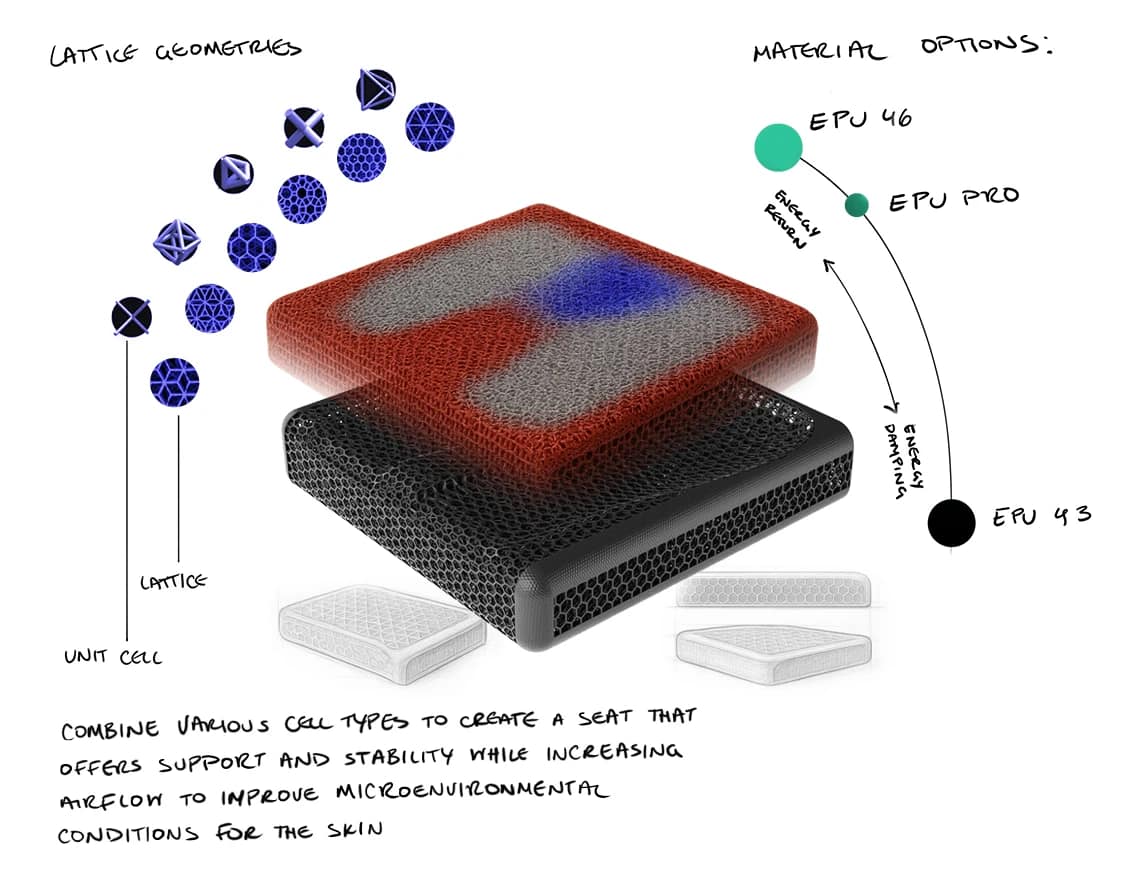

Digital Comfort and Multi‑Zone Lattice Design

Carbon lattice wheelchair cushions leverage multi‑zone lattice structures that allow precise modulation of stiffness and elastic response across the seating surface. Using tools like the Carbon Design Engine software, designers can create cushions with:

Soft zones for cushioning and comfort

Stiffer zones for postural support and stability

Controlled energy return to reduce fatigue from repetitive pressure or motion

This advanced engineering enables full customization, making Carbon lattice cushions suitable for both medical users requiring pressure management and active users seeking dynamic performance.

For example, a cushion designed for an active user may feature softer zones in the rear for shock absorption and firmer zones on the sides to stabilize the pelvis and improve balance.

Breathability and Optimized Microclimate

The open structure of Carbon lattice naturally channels airflow, helping to:

Reduce heat and humidity buildup

Improve thermal comfort during extended use

Protect the skin from irritation and pressure‑related complications.

Paired with multi‑zone design, this ventilation strategy helps maintain healthy skin and reduce friction, a key factor in preventing pressure ulcers and other skin conditions.

Pressure Distribution and Energy Absorption

The innovation of lattice design goes beyond simple pressure relief. When loading a lattice cushion, forces are redistributed through interconnected struts and nodes, reducing peak pressure and providing consistent support across a wider area.

Key advantages:

Long‑term injury prevention by reducing cumulative tissue stress

Improved immediate comfort through adaptive support

Reduced joint strain and fatigue, enhancing mobility and daily function.

This dual function, pressure management and controlled energy absorption, distinguishes Carbon lattice cushions from traditional materials that often fail to maintain performance over time.

Superior Cleanability and Durability

Carbon’s lattice materials are not only durable but also easier to clean and maintain than traditional foam products. The open lattice structure prevents fluid entrapment and allows thorough washing, helping to maintain hygiene over prolonged use.

Extreme Customization: The Future of Wheelchair Cushions

Carbon lattice technology supports precise tunability of parametric variables such as strut diameter, cell shape, and lattice spacing. This means cushions can be engineered to:

Absorb forces in targeted areas

Redistribute pressure across key zones

Provide adaptive support based on user activity level

This versatility benefits a wide range of users:

Long‑term wheelchair users

Athletes and active individuals

Personalized medical and rehabilitative seating needs

The Science of Support: Pressure, Energy, and Protection

True comfort extends beyond softness. It’s about achieving a balance between even pressure distribution, controlled energy absorption, and long‑term physiological protection. Lattice cell configurations are engineered to spread load across interconnected elements, significantly reducing peak pressure and protecting against both short‑ and long‑term stress.

Carbon DLS™ enables designers to tailor the performance of these structures with precision, making cushions that provide softness where needed and firmness where essential for support (carbon3d.com).

Versatility and Broader Applications

Although designed for wheelchair seating, the principles of Carbon lattice technology apply to a range of ergonomic seating and comfort products including:

Advanced medical seating systems

Performance gear for sports and outdoor activities

Lifestyle products that demand comfort and protection.

Every application benefits from enhanced comfort, resistance, and durability, offering tailored solutions for diverse needs.

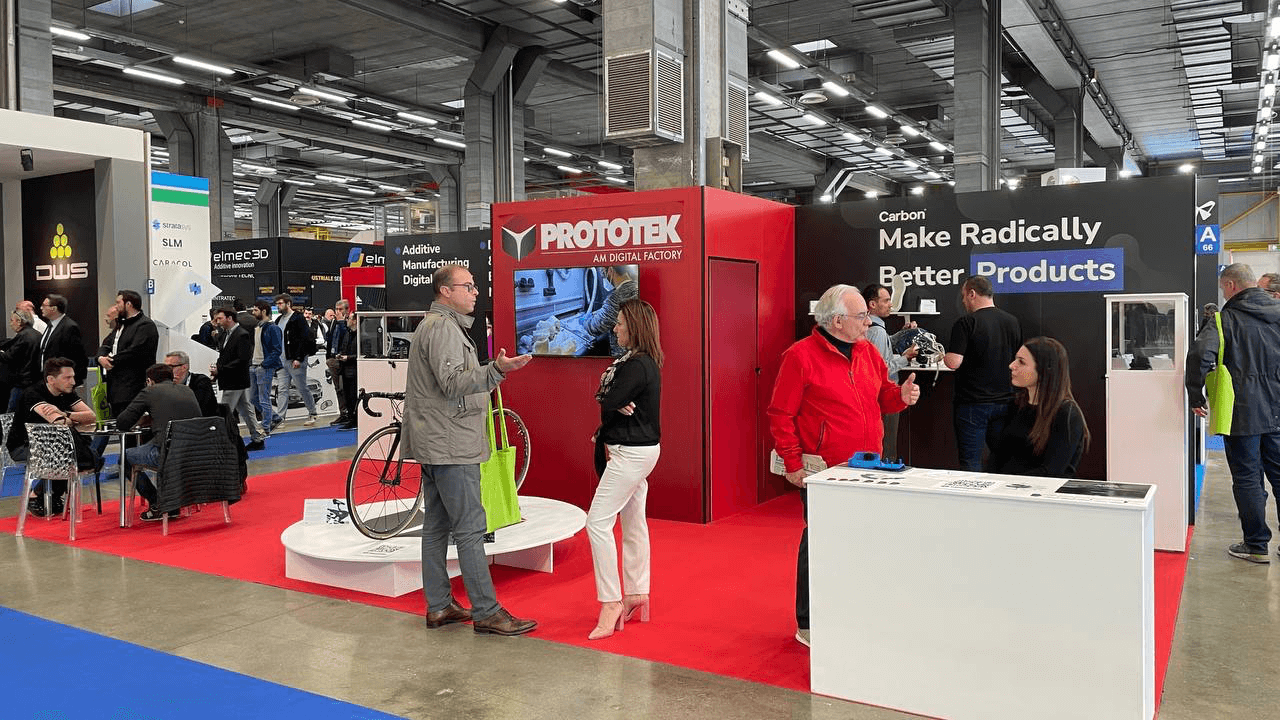

Prototek: Trusted Carbon 3D Technology Partner

Prototek is a reliable global partner for complex Carbon DLS™‑based projects, supporting clients from concept to production. Prototek’s services include:

Expert design and material consultation

Rapid, accurate production with Carbon DLS™

Full customization of color, stiffness, and geometric features.

By partnering with Prototek, customers leverage the full advantages of Carbon 3D technology: personalized comfort, controlled energy absorption, enhanced breathability, and unmatched durability.

EPU 46 Carbon 3D: High‑Performance Material

EPU 46 is a high‑performance polyurethane elastomer developed by Carbon 3D for advanced applications such as wheelchair cushions, midsoles, saddles, and ergonomic grips.

Key characteristics:

High strength with controlled elasticity

Energy return up to 100% better than previous formulations

40% bio‑based composition, with solvent‑free cleaning compatibility

Biocompatible for skin‑contact applications.

EPU 46’s tunable properties, including color, durometer (Shore 56A–78A), and geometric customization, enable design flexibility across medical, consumer, and performance applications.

Applications include:

Custom midsoles with variable compression zones

High‑performance ergonomic saddles

Breathable ergonomic grip components.

Combined with Carbon DLS™, EPU 46 extends the possibilities of tailored comfort and protection without compromising precision or durability.

FAQ: All You Need to Know About Carbon Lattice Cushions

1. What makes Carbon lattice cushions better than foam?

Carbon lattice distributes pressure more evenly and maintains long‑term performance without material breakdown.

2. Can color and stiffness be customized?

Yes — EPU 46 and Carbon DLS™ allow full customization of color, stiffness, and geometry.

3. Are these cushions suitable for medical use?

Yes — the materials are biocompatible and ideal for prolonged skin contact in clinical settings.

4. How are they maintained?

Open lattice design allows effective cleaning compared to traditional foam products.

Choosing Carbon lattice wheelchair cushions, engineered with EPU 46 and produced with Prototek and Carbon DLS™, means investing in comfort, safety, and innovation on a global scale.

Contact us now to customize your cushion’s shape, stiffness, and color — and to start your tailored seating project.