Prototek adds its 7th Carbon DLS 3D Printer:

expanding capacity and industrial performance

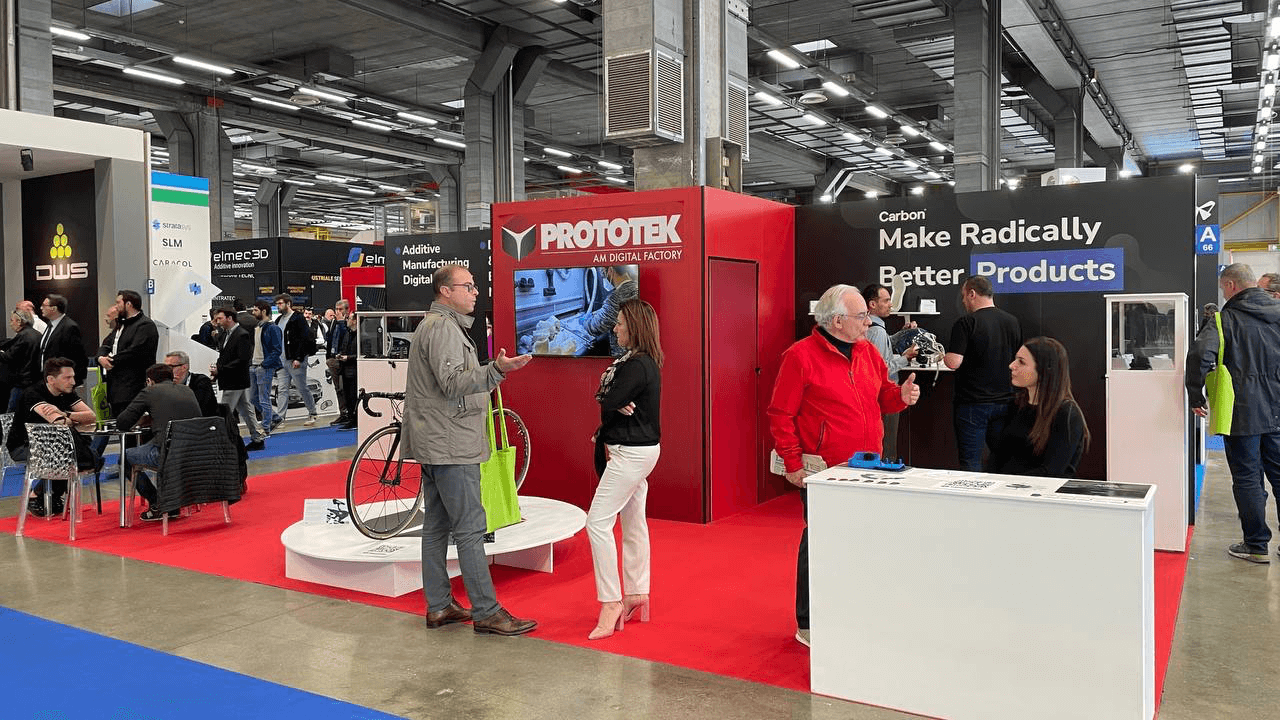

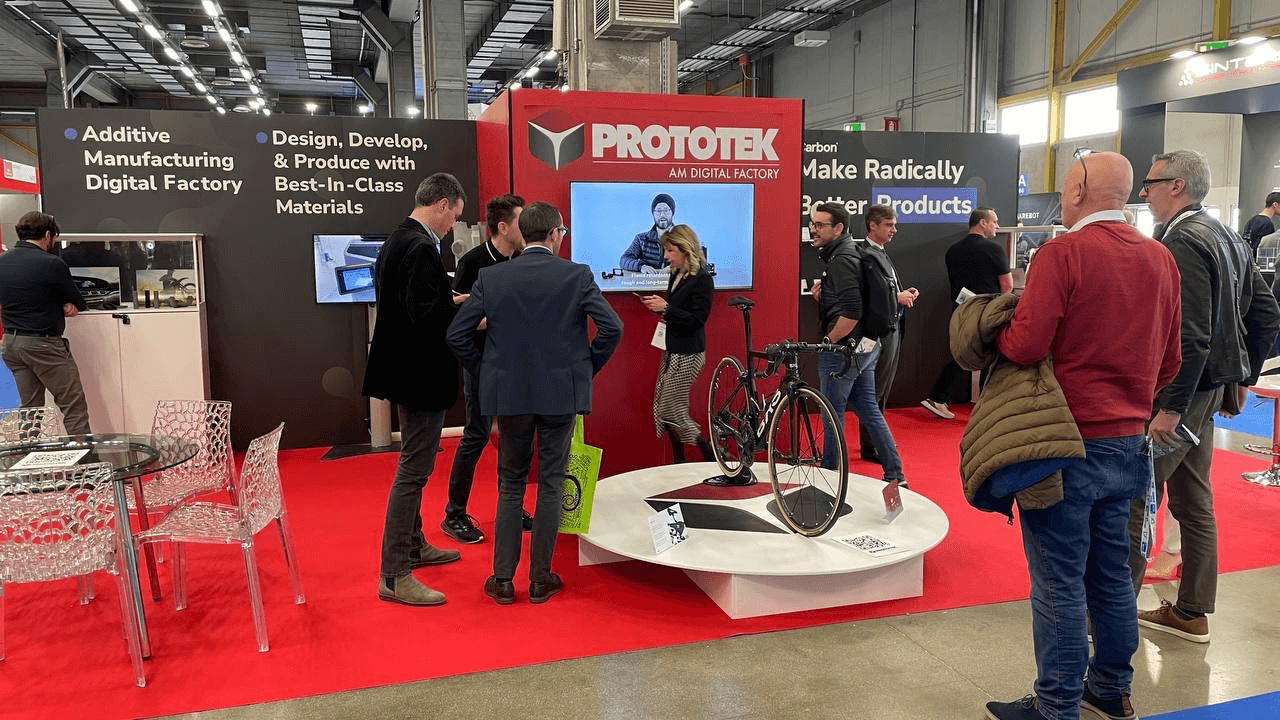

Prototek continues to invest in high-end 3D printing technology with the arrival of its seventh Carbon DLS (Digital Light Synthesis) printer.

This major step strengthens its production capacity and ability to meet the growing demand for functional parts and high-performance prototypes.

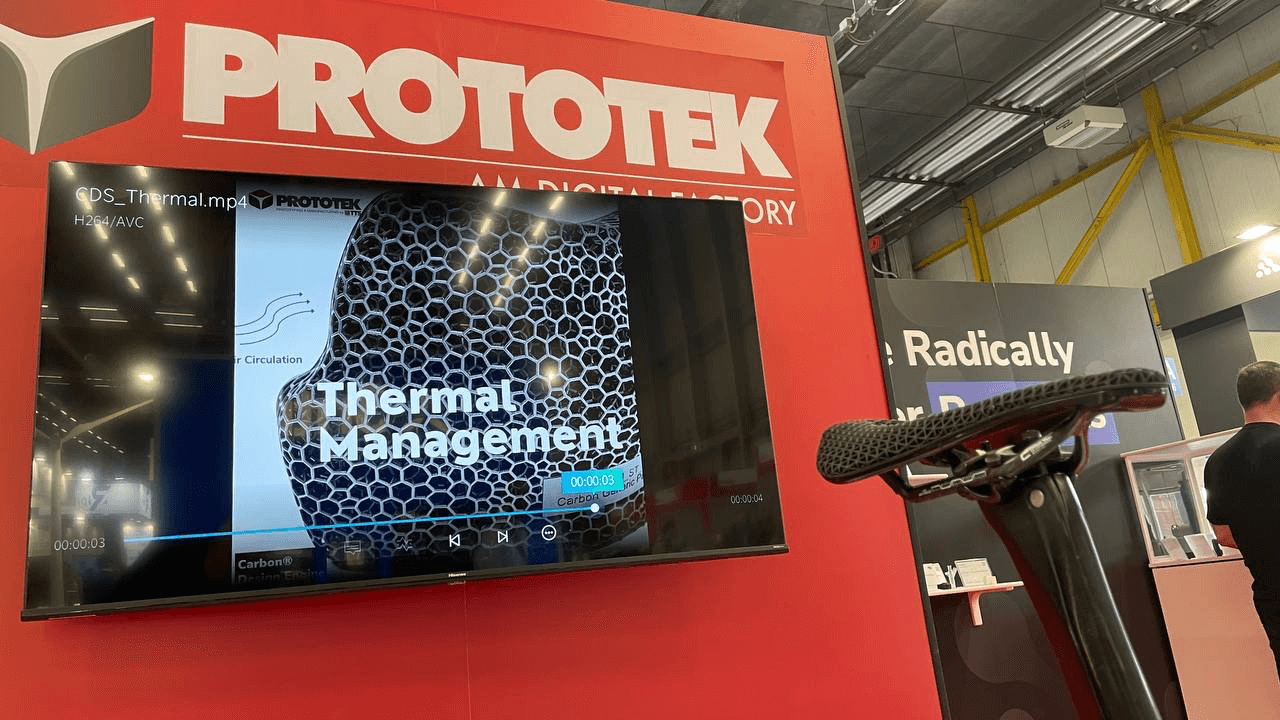

Carbon DLS: advanced technology for industrial 3D Printing

Carbon DLS™ technology stands out for its ability to produce solid, isotropic parts with complex geometries, smooth surfaces, and mechanical properties comparable to traditional engineering materials.

Unlike other additive manufacturing technologies, DLS combines the speed of liquid photopolymerization with the precision and durability of technical materials, making it ideal for functional prototyping and end-use production.

Boosting production capacity and reducing lead times

With the addition of the seventh Carbon DLS 3D printer, Prototek significantly increases its manufacturing capacity, allowing the company to:

Reduce lead times for prototypes and functional parts by printing multiple components simultaneously.

Manage complex orders requiring high-performance materials and intricate geometries.

Accelerate experimentation and scalability, thanks to an expanded, fully operational DLS machine fleet.

This strategic expansion enables Prototek to deliver consistent performance while meeting demanding production schedules for European and international clients.

High-performance 3D printed components

Carbon DLS printing delivers exceptional mechanical properties — impact resistance, controlled flexibility, and durability even under heavy mechanical stress.

This makes the technology ideal for industries such as automotive, industrial manufacturing, medical devices, consumer goods, and sportswear, where precision, reliability, and aesthetic quality are critical.

Polyurethane elastomers for advanced 3D printing

Among Carbon’s most innovative materials are polyurethane-based elastomers, used to produce flexible yet durable parts that maintain structural integrity over time.

These materials are ideal for functional seals, gaskets, midsoles, and vibration-damping components, offering performance levels unattainable with conventional 3D printing resins.

Prototek’s expertise with Carbon elastomer materials allows customers to move from prototype to production faster , while maintaining consistency, precision, and certified quality.

Investing in continuity, quality, and reliability

This new investment not only boosts capacity but also strengthens production continuity and process reliability.

With seven Carbon DLS 3D printer systems, operating on a 24/7 production schedule, Prototek can handle larger orders and complex geometries without compromising delivery time or quality.

Each part is produced under strict quality standards, ensuring consistent mechanical properties and repeatability across batches.

The DLS process: precision and surface excellence

At the heart of the Carbon DLS process is light-controlled polymerization, which ensures uniform, smooth surfaces with minimal need for post-processing.

This process achieves exceptional dimensional accuracy, essential for functional components that must fit precisely with existing mechanical or electronic assemblies.

Innovation and technical support for Industry

The seventh Carbon DLS 3D printer reinforces Prototek’s role as a trusted production partner offering scalable, repeatable, and high-quality additive manufacturing solutions.

With its advanced printer fleet, the company supports both rapid prototyping and low-to-medium volume production of functional parts, helping clients reduce product development time and gain a competitive advantage in their markets.

Leadership in industrial 3D Printing

This milestone marks another step forward in Prototek’s mission to deliver cutting-edge 3D printing services, focusing on:

Superior surface quality and geometric accuracy

Process repeatability and long-term reliability

Expanded production capacity and scalability

Support for high-performance industrial applications

Carbon DLS 3D printing once again confirms Prototek’s position as a strategic partner for European manufacturers seeking innovative, reliable, and scalable additive solutions.

Consulting and on-demand support

For companies looking to explore Carbon DLS applications or the potential of polyurethane elastomers for 3D printing, Prototek offers technical consulting and continuous support.

Our specialists help you identify the best materials, geometries, and finishes for your project, from initial concept to full-scale production.

With its seventh Carbon DLS 3D printer, Prototek consolidates its technological leadership in industrial additive manufacturing, continuing to deliver advanced solutions for functional prototyping and end-use production, opening new opportunities for B2B clients across Europe.