3D Printing in Sports: Transforming Performance and Protection

3D printing in sports is no longer just a prototyping tool—it’s now a functional technology driving performance, comfort, and durability. Leading sports brands are leveraging advanced 3D printing technologies and Carbon polyurethane materials to create high-performance equipment that meets both ergonomic and technical requirements.

Whether you’re a designer, engineer, or athlete, understanding how 3D printing can enhance sports gear is crucial for innovation.

What you’ll find in this free PDF:

3 real-world applications: Top sports brands that partnered with Prototek, including Selle Italia (cycling), Filippi (rowing), and BoxingHandGrenade (combat sports).

Use of Carbon® DLS™ technology, leveraging advanced polyurethane resins EPU41 and EPU46.

Technical parameters: biomechanics, materials, lattice geometries.

Proven results: enhanced comfort, impact absorption, and energy return.

Potential use cases: sports footwear, midsoles, insoles, grips, and protective gear.

Why 3D Printing in Sports matters

The application of 3D printing in sports covers a wide range of performance-driven solutions, including:

Custom sports footwear, midsoles, and insoles.

Protective gear like helmets, pads, and grips.

Ergonomically optimized seating for rowing, cycling, and other sports.

By using technologies such as Carbon® DLS™ and HP Multi Jet Fusion, brands can produce lightweight, durable, and impact-absorbing components tailored to individual athletes or specific use cases.

Carbon 3D Polyurethane resins like EPU41 and EPU46 allow for flexible, high-strength materials suitable for rigorous performance standards.

Explore how Carbon® DLS™ is revolutionizing sports footwear, protective equipment, and performance accessories.

Real-World case studies

Discover how top brands partnered with Prototek to turn innovative ideas into market-ready, high-performance products.

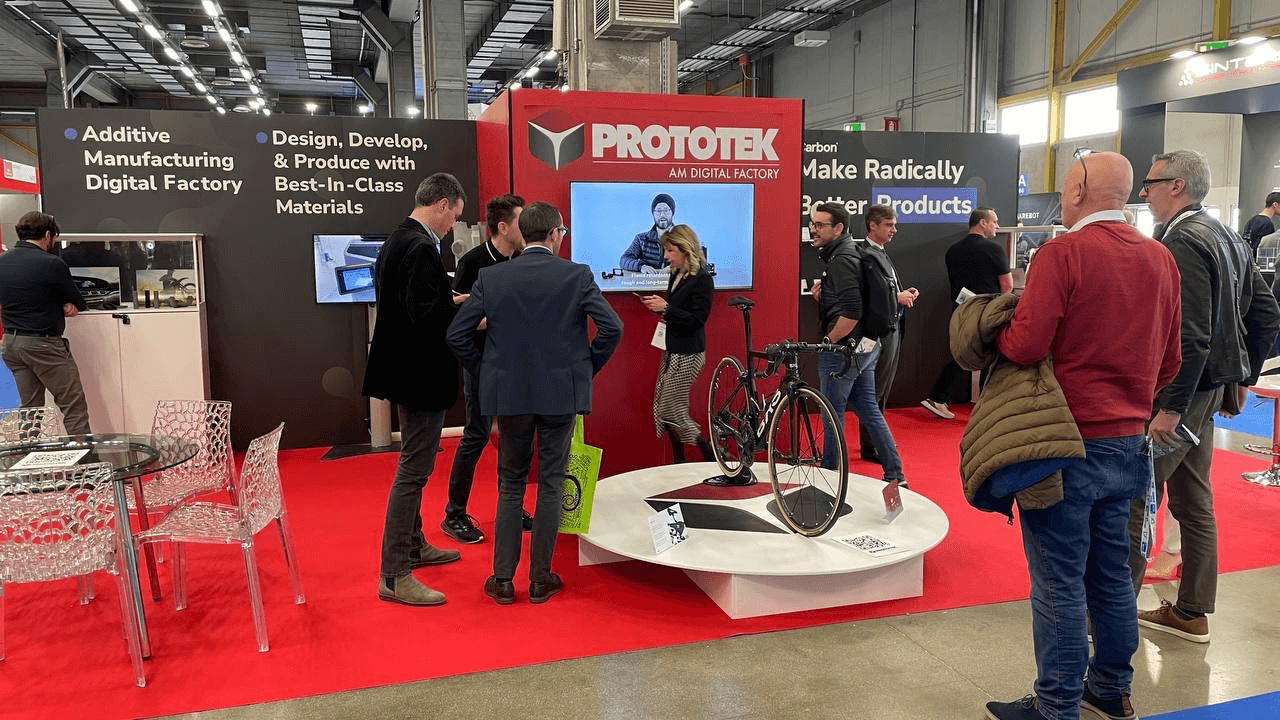

Case Study #1 – Selle Italia (Cycling) – EPU41 Carbon®

A high-performance cycling saddle featuring a lattice structure for superior comfort and durability.

Applications: Insoles, heel cups, protective pads for elbows, knees, and grip enhancements.

Impact: Improved energy return, reduced fatigue, and enhanced ergonomic performance.

Case Study #2 – Filippi (Rowing) – EPU46 Carbon®

An ergonomic seat design for rowers, optimized for dynamic response and comfort.

Applications: Technical sports footwear, running inserts, midsoles, and padding.

Impact: Enhanced comfort, reduced pressure points, and improved biomechanics.

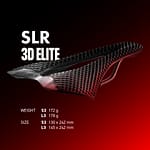

Case Study #3 – BoxingHandGrenade (Combat Sports) – EPU41 + Carbon®

Grip bars for boxing gloves featuring a Voronoi lattice structure for superior impact absorption.

Applications: Helmets, insoles, grips, protective gear for combat and extreme sports.

Impact: High energy absorption, durability, and ergonomic fit for repetitive impact sports.

Advanced materials and technology for 3D printing in sports

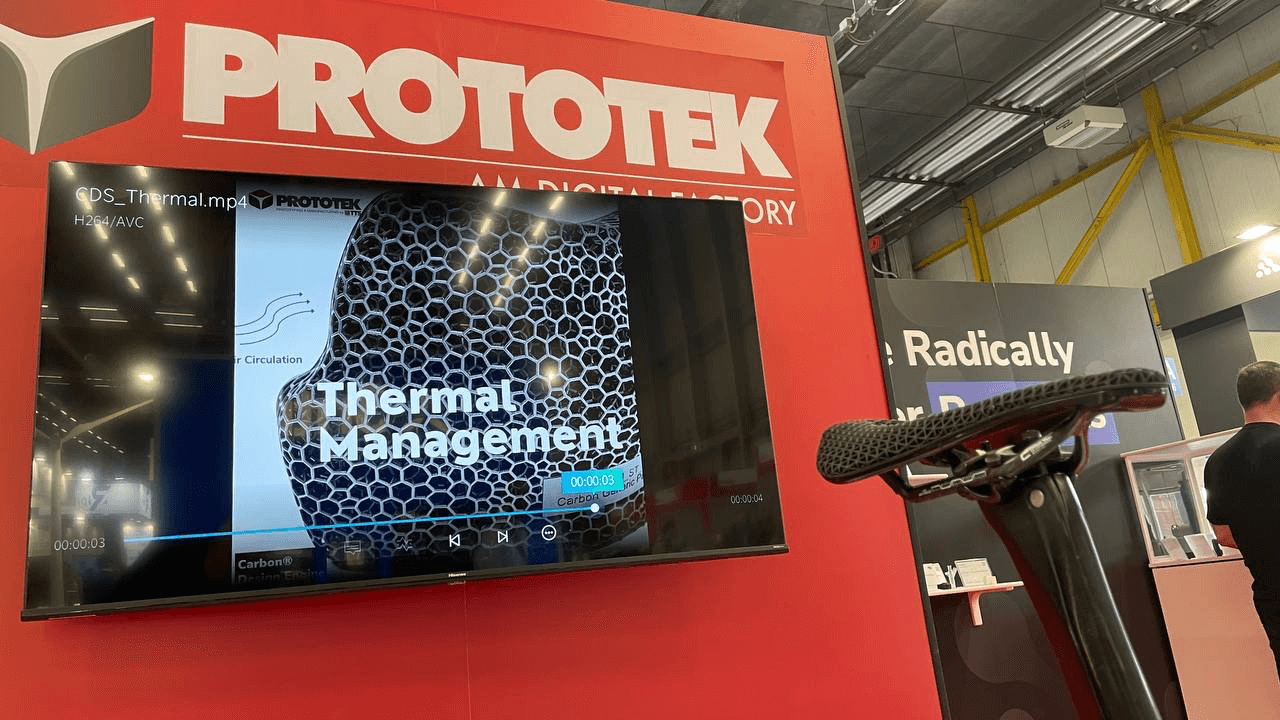

Polyurethane elastomers like EPU41 and EPU46 provide flexibility, resilience, and strength, making them ideal for sports applications where comfort and performance are critical. Coupled with Carbon® DLS™ technology, these materials enable the creation of complex lattice structures that traditional manufacturing cannot achieve.

Key benefits include:

Optimized energy return and shock absorption

Customizable ergonomic designs

Rapid prototyping to full-scale production

Reduced material waste and sustainable manufacturing.

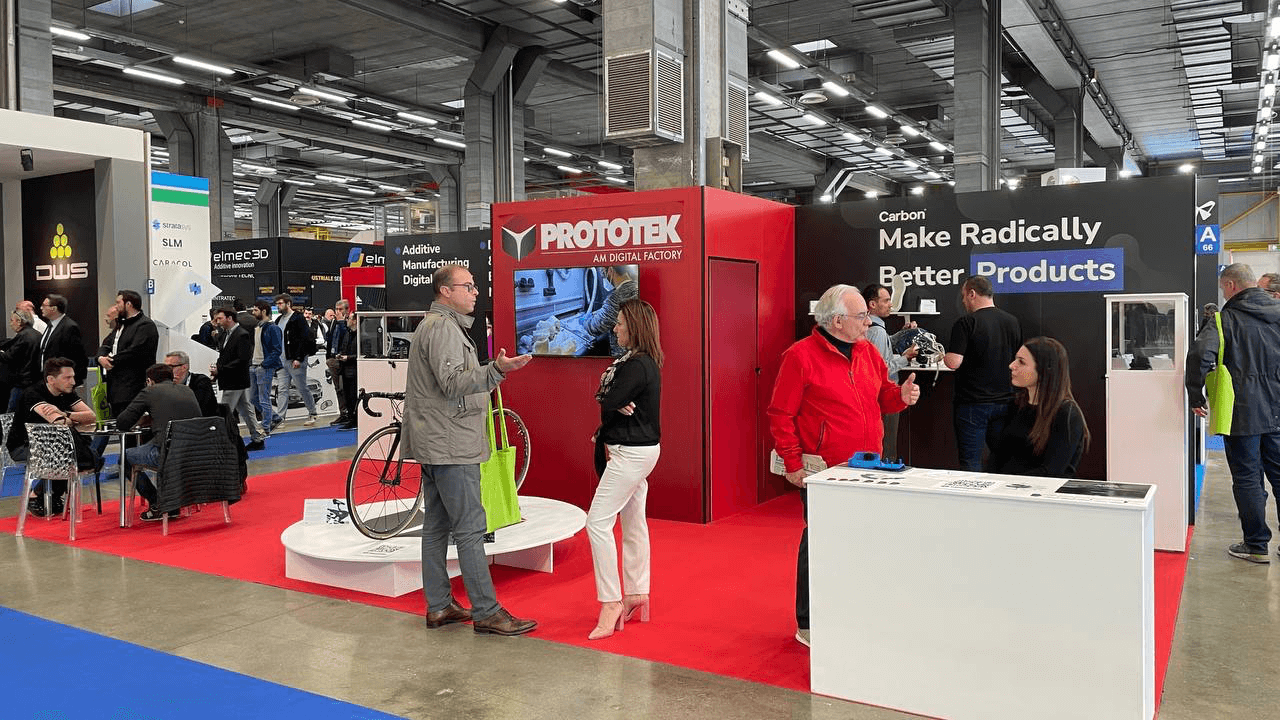

Why choose Prototek for 3D printing in sports projects?

Prototek supports every stage of 3D printing in sports projects, from design consultation to full-scale production. With access to technical materials, engineering expertise, and performance optimization, Prototek ensures your project achieves both functional and market-ready results.

Whether you are evaluating a new sports footwear concept, designing protective gear, or developing custom performance accessories, Prototek can guide you through the entire 3D printing process.

Potential use cases

The applications of 3D printing in sports are extensive and growing:

- Custom running shoes and insoles

Impact-resistant protective gear

Enhanced grips for combat sports

Lattice-optimized seating and ergonomic supports.

By integrating advanced materials and 3D printing processes, brands can deliver products that enhance athlete performance, comfort, and durability, while staying ahead of the competition.

Looking to evaluate your project?