CARBON 3d

Digital Light Synthesis™

Carbon 3D Printing for Advanced Industrial Production | Digital Light Synthesis™ (DLS™)

Revolutionizing Manufacturing with Digital Light Synthesis™

Carbon 3D Printing, powered by Digital Light Synthesis™ (DLS), represents a breakthrough in additive manufacturing. This cutting-edge technology uses digital light projection, oxygen-permeable optics, and next-generation liquid resins to create parts with exceptional mechanical properties, fine resolution, and superior surface finish.

Unlike traditional resin-based 3D printing methods, Carbon 3D DLS produces components with the surface quality of photopolymers and the strength, durability, and stability comparable to high-performance thermoplastics.

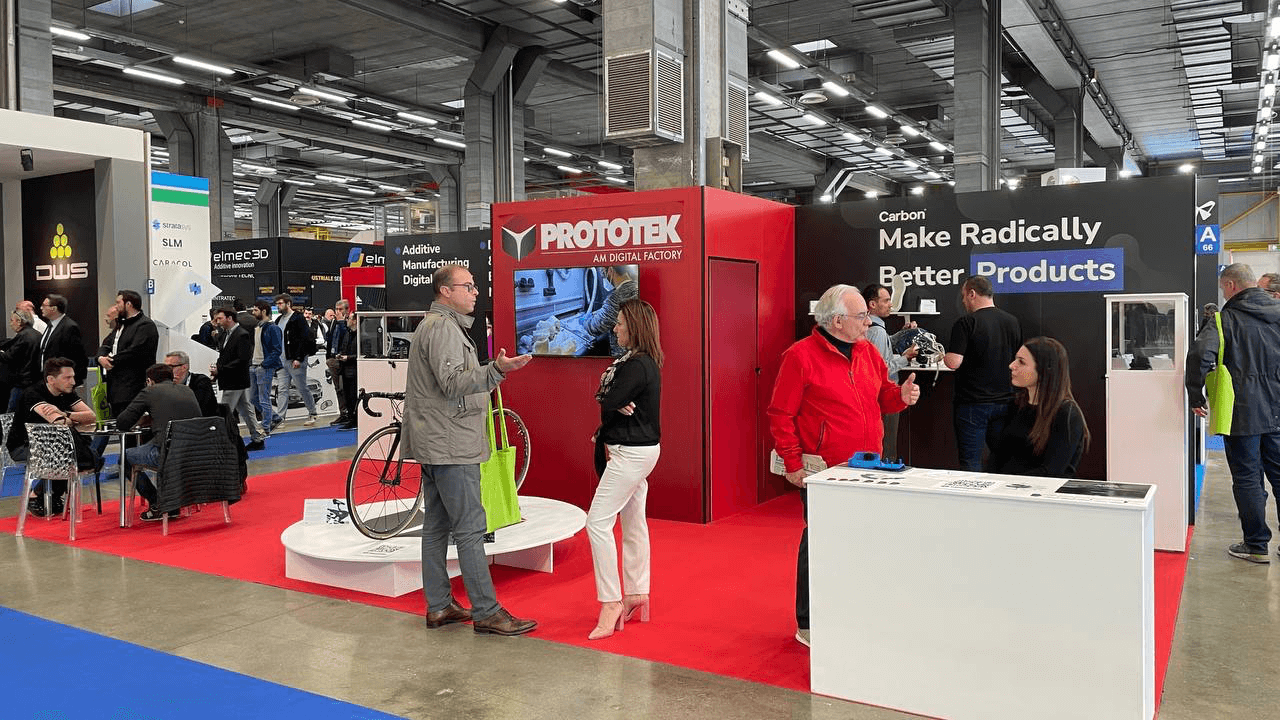

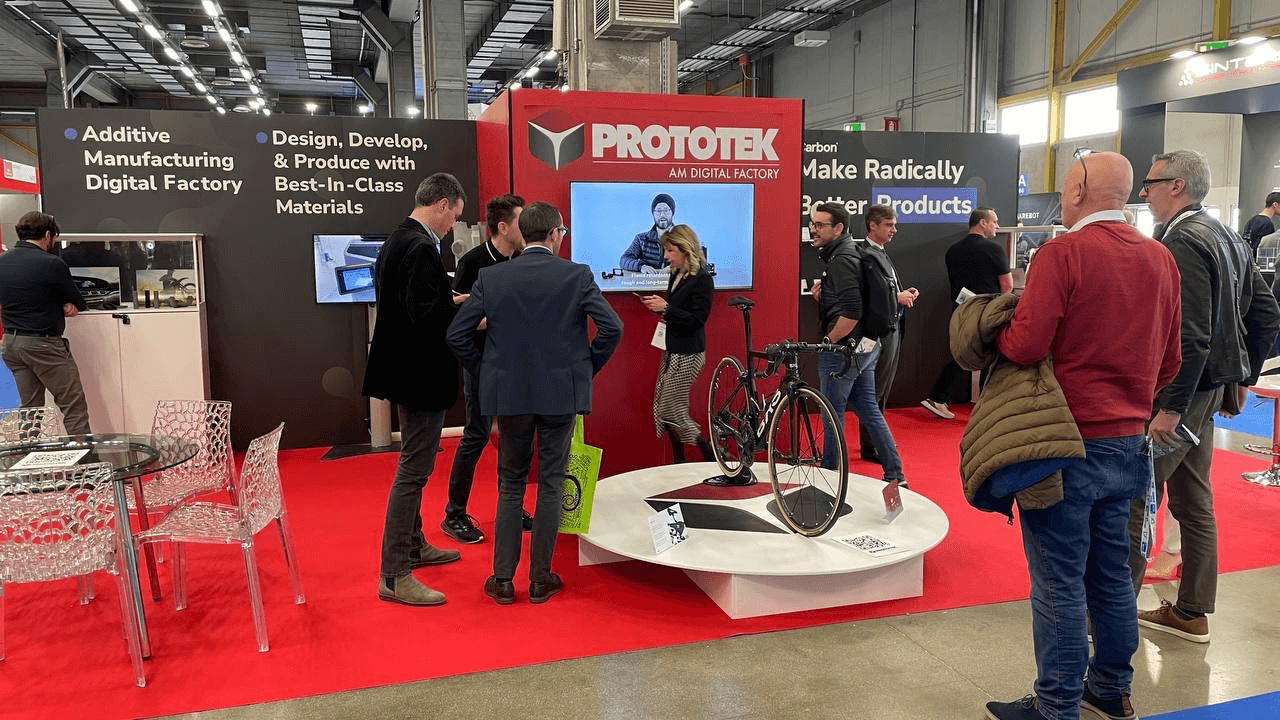

Prototek and the Excellence of Carbon 3D DLS™ Technology

Prototek leverages Carbon 3D DLS™ technology to enable rapid and scalable production, dramatically reducing development time and allowing efficient printing of large part volumes.

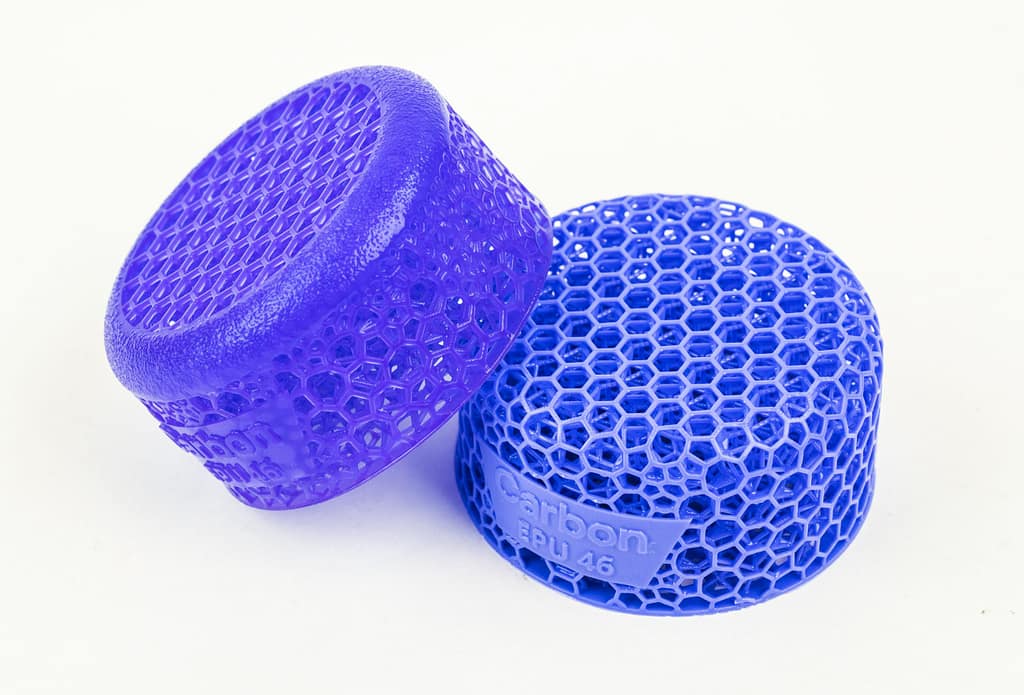

By combining advanced elastomeric materials like EPU 46 with sophisticated lattice geometries, Prototek offers unmatched design freedom. The result: functional prototypes and end-use parts that balance softness and rigidity precisely where needed.

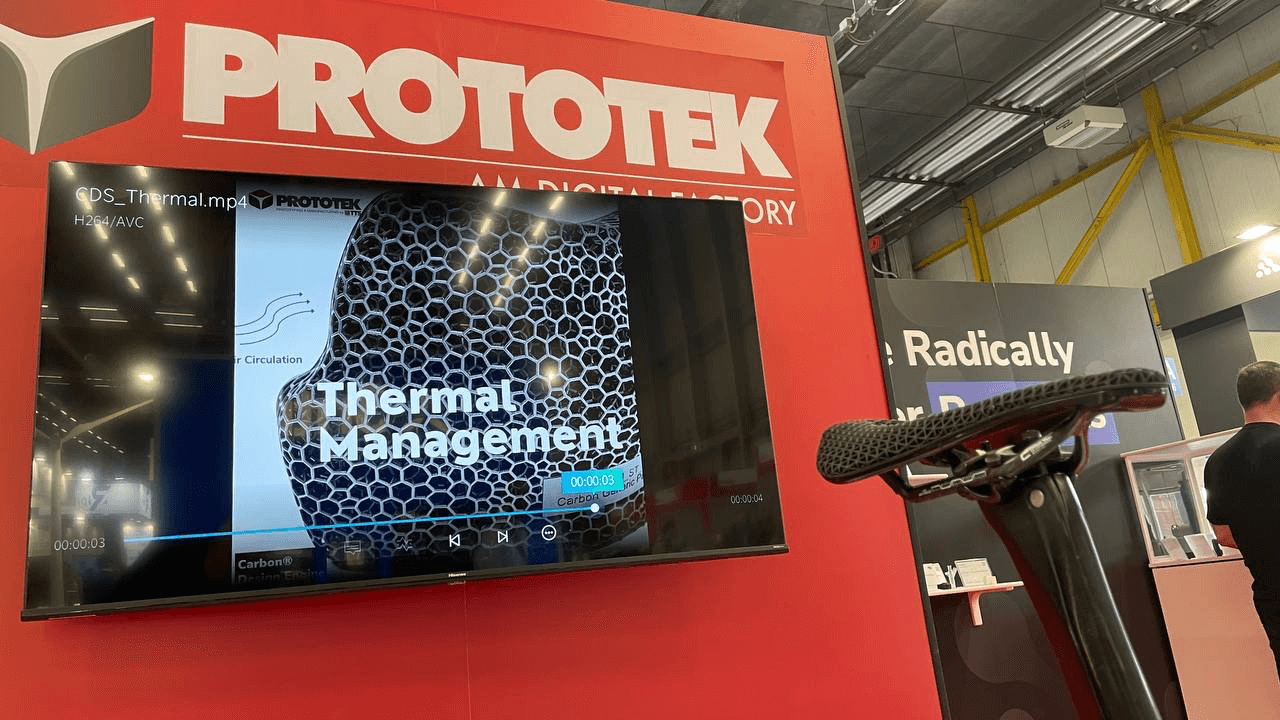

The performance advantage of Carbon 3D DLS comes from its variable-density lattice structures, which enhance comfort, energy absorption, and shock resistance, ideal for applications such as helmet padding, seating systems, and performance gear.

Each prototype can be fully customized in terms of material, geometry, and color, ensuring that every component meets specific functional and aesthetic requirements.

Durability and Long-Term Reliability

Prototek’s selection of Carbon 3D materials guarantees long-term durability and mechanical integrity, even in demanding environments. Whether for prototyping or full-scale production, these components deliver consistent industrial-grade performance.

Competitive Advantages of Carbon 3D Printing

- Variable Softness and Rigidity:

Carbon 3D DLS enables complex variable-density lattice structures, allowing optimal comfort, energy return, and impact absorption. - Versatile Applications:

Perfect for sports equipment, wearable devices, fashion accessories, automotive interiors, and product design, Carbon DLS accelerates the prototyping and production process with unmatched flexibility. - Superior Performance:

Engineered for impact absorption, customized comfort, and mechanical strength, ensuring consistent results across small or large batches. - Advanced Materials:

Carbon’s EPU elastomers and rigid resins provide excellent elasticity, toughness, and stability, ideal for high-performance and engineering-grade parts. - Precision and Speed:

With Carbon 3D DLS, Prototek guarantees rapid turnaround times and fine detail resolution, significantly reducing design-to-production lead times.

Inside the Carbon 3D Printing Process

The Digital Light Synthesis™ process is based on Continuous Liquid Interface Production™ (CLIP™) and Carbon’s programmable liquid resins. CLIP™ utilizes digital light projection through an oxygen-permeable window, a concept first introduced in a groundbreaking Science journal publication.

Traditional resin 3D printing produces parts that are often brittle and prone to aging or crystallization. Carbon’s dual-component materials overcome this limitation: after the initial UV photopolymerization, a thermal post-cure chemically activates a secondary reaction that transforms the printed part into a true thermoplastic-equivalent structure.

How Light Shapes Matter: The CLIP™ Process

with Caron 3D printing

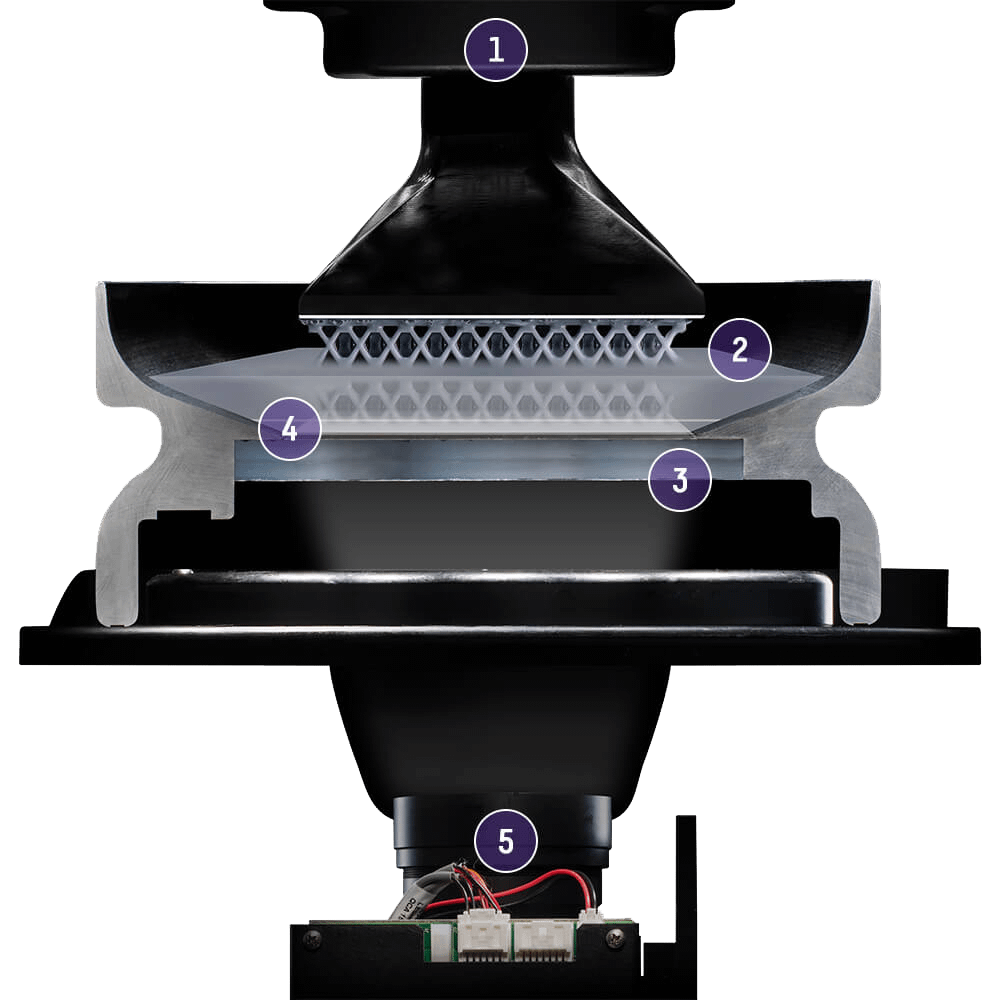

CLIP™ is a photochemical process that uses UV light to solidify a specialized liquid resin. The UV image sequence is projected through an oxygen-permeable window beneath the resin tray, creating a continuous build zone where the part forms seamlessly.

Unlike conventional layer-by-layer DLP printing, CLIP™ continuously pulls the solid part upward, producing isotropic components with uniform density and no visible layer lines. This continuous process eliminates lateral stress during printing and allows faster, smoother, and stronger part creation.

Core Components of the System

- Build Platform

- Resin Vat

- Oxygen-Permeable Window

- Dead Zone (Continuous Build Interface)

- UV Light Engine and Motorized Lift System.

dead zone

The “dead zone” is key to the process; it’s the microscopic gap between the window and the part being printed.

This oxygen-rich zone prevents the resin from curing directly on the window, enabling constant resin flow and continuous printing.

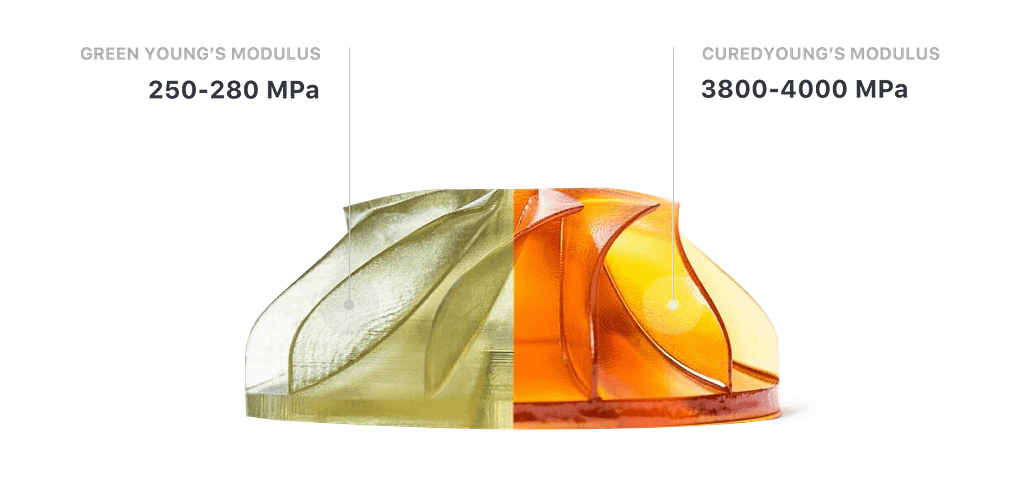

Thermal Activation: achieving true Thermoplastic Properties

At the end of the printing phase, the components are UV-cured and partially solidified. During the thermal post-cure, the second reactive component in Carbon’s resin activates, completing the polymerization and producing stable, strong, and durable parts.

This dual-stage curing process ensures outstanding mechanical performance, dimensional stability, and long-term resistance—qualities previously unachievable in resin-based 3D printing.

Exceptional Surface Quality and Mechanical Performance

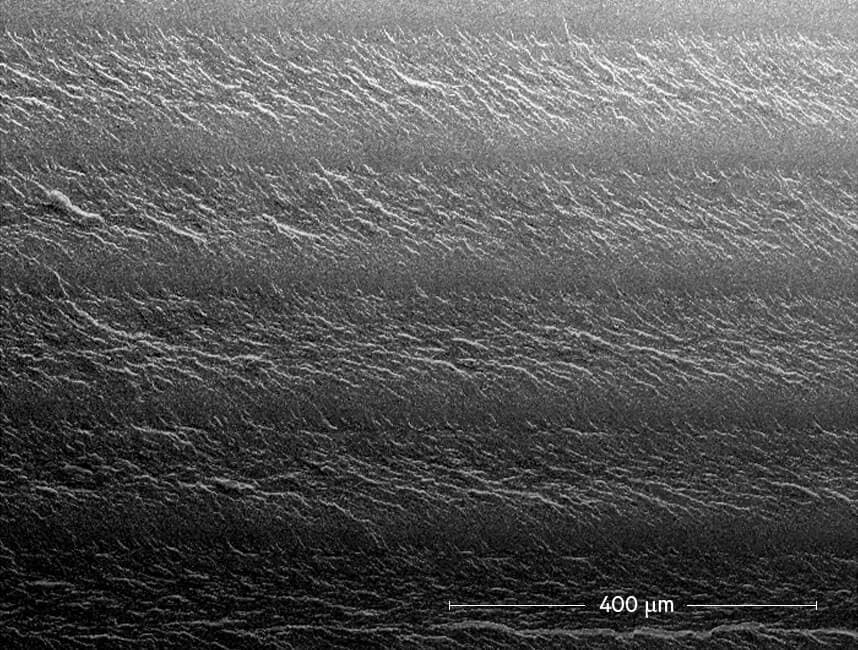

Traditional resin 3D prints often suffer from weakness along the Z-axis due to their layer-by-layer construction.

The continuous build process guarantees:

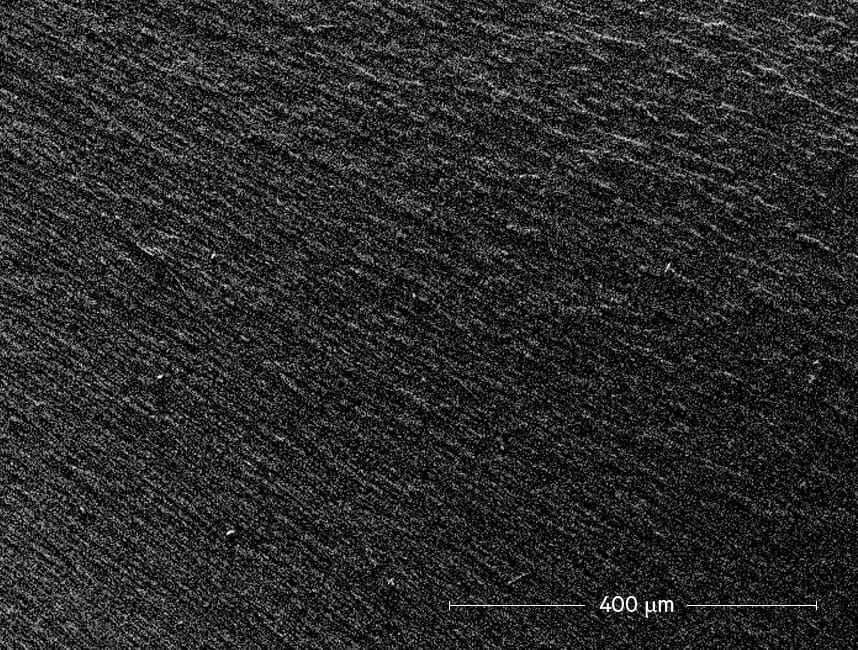

Smooth, injection-mold-quality surface finishes

High accuracy and detail definition

Superior isotropy and durability

This makes Carbon 3D DLS™ ideal not only for prototypes but also for end-use industrial production.

Digital Light Synthesis™

Carbon 3D DLS™ (Digital Light Synthesis™) produces isotropic parts with consistent density and strength in every direction.

DLP 3D PRINTING

3D-printed parts are notoriously inconsistent. Their mechanical properties vary depending on the direction in which the parts were printed due to the layer-by-layer construction.

Engineering Design, Redefined

Modern CAD and simulation software allow engineers and designers to push the limits of creativity—and Carbon 3D DLS™ brings those designs to life faster than ever before.

The process enables geometries impossible with traditional manufacturing, supporting lightweight structures, custom lattice patterns, and advanced functional designs.

Discover how Carbon 3D DLS™ reshapes the future of design and product engineering.

Prototek: leading certified Carbon Partner in Italy

Prototek proudly holds the distinction of being the only partner in Italy equipped with seven active Carbon 3D printers, operating 24/7 from Sunday night to Friday evening.

This extensive production capacity allows Prototek to deliver high-quality Carbon 3D printed parts with industrial precision and fast turnaround, serving industries from automotive and aerospace to sportswear and medical devices.

Request a consultation with Our Expert