Knee brace made with 3D printed TPU:

flexibility and durability with ESTANE® 3D TPU M88A

In the world of industrial 3D printing TPU, material selection is crucial.

Advanced thermoplastic polyurethanes, such as ESTANE® 3D TPU M88A from Lubrizol, now allow engineers to create components that combine flexibility, mechanical strength, and long-term durability, features difficult to achieve with traditional manufacturing.

Thanks to collaboration between Prototek as Italian leader in 3D printing TPU solutions and PUNTOZERO-Design For Additive Manufacturing studio, a fully functional knee brace was produced via 3D printing TPU using HP Multi Jet Fusion (MJF).

This project demonstrates the full potential of functional, flexible 3D‑printed parts.

Why Choose 3D Printing TPU?

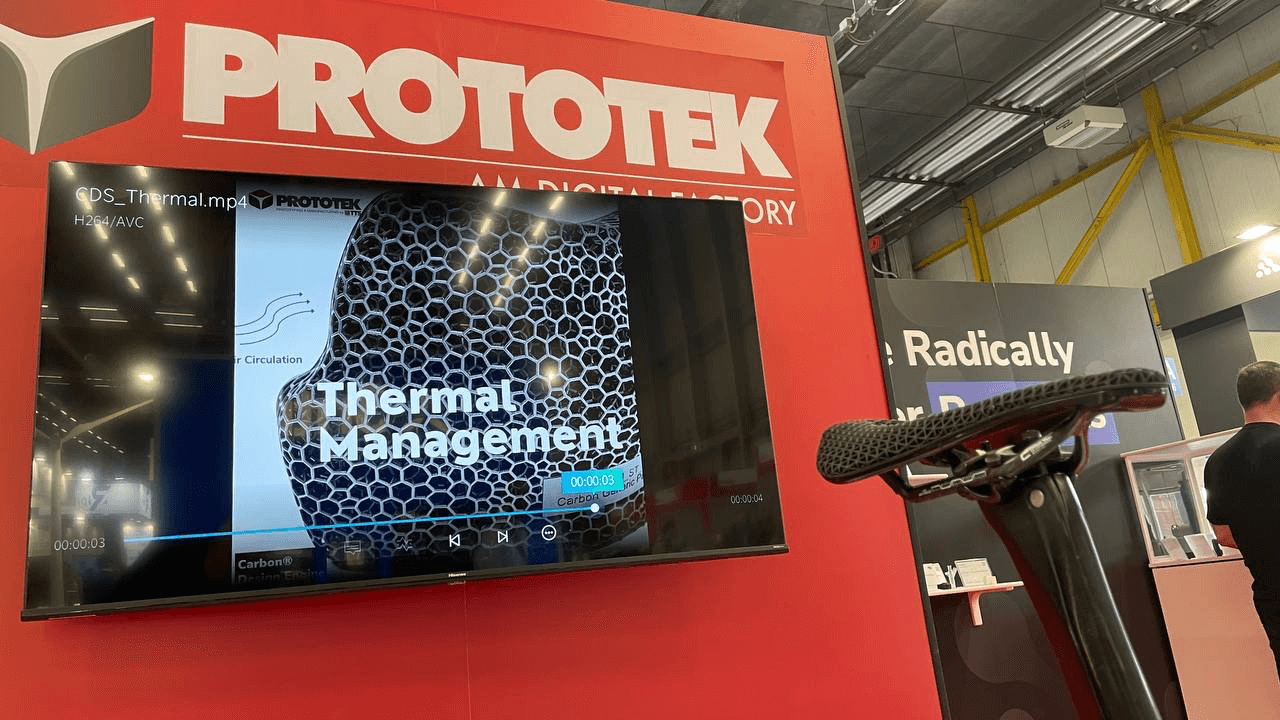

Thermoplastic polyurethane (TPU) is a unique 3D printing material that merges rubber-like elasticity with plastic-like resistance. In the ESTANE® 3D TPU M88A formulation — certified for HP MJF — it offers several advantages:

Controlled deformability without failure – ideal for parts undergoing repeated stress or bending.

Abrasion and chemical resistance – perfect for industrial or outdoor applications.

Dimensional stability under load – maintaining shape and precision over time.

High-quality surface finish and detail resolution – thanks to HP Multi Jet Fusion technology.

These properties make 3D printing TPU a reference material for industries including sports, automotive, medical, and industrial engineering.

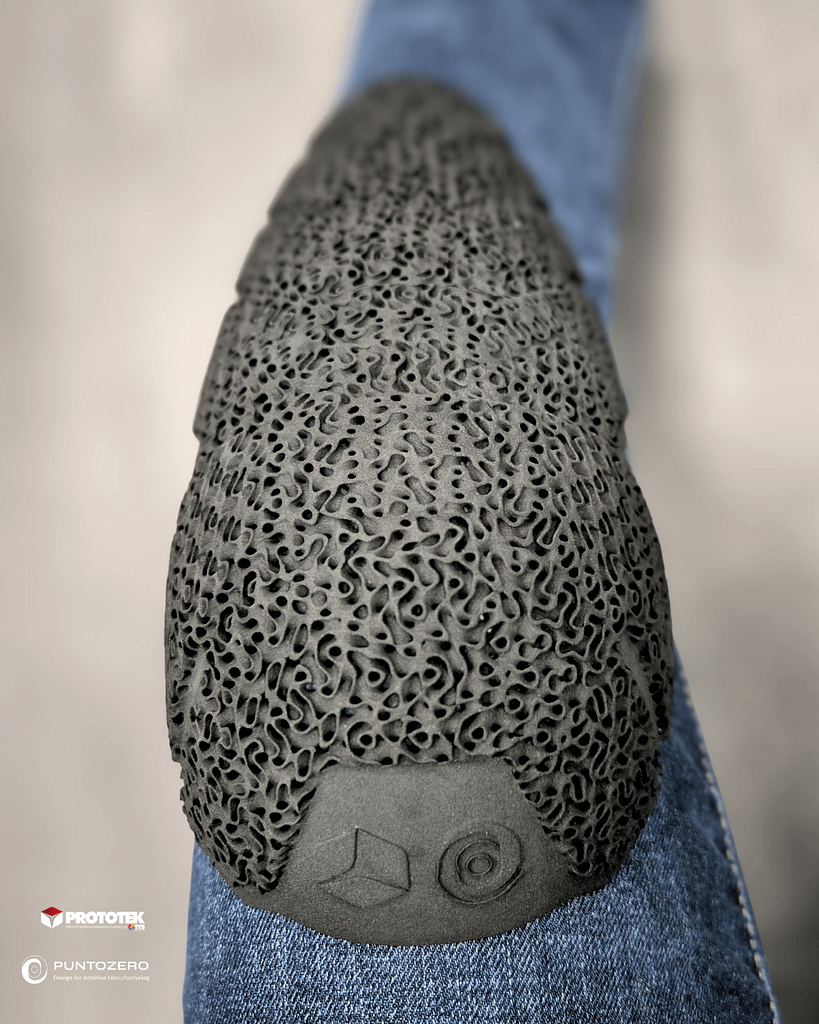

Case Study: a functional 3D‑Printed Knee Brace

Working with PUNTOZERO DfAM, Prototek developed an ergonomic, high-performance knee brace entirely manufactured with 3D printing TPU.

The goal was to demonstrate how 3D printing TPU can overcome traditional manufacturing limits, combining custom design with advanced mechanical functionality.

The knee brace embodies three key qualities:

Flexibility – its structure enables natural movement and controlled deformation without damage.

Strength & durability – the TPU formulation resists wear, impacts, and aggressive fluids.

Long-lasting performance – even after extensive stress tests, it retains its properties and dimensions.

HP MJF technology ensured consistent surface finish, precise details, and repeatability, making the knee brace a functional prototype ready for production.

Beyond the Prototype: new frontiers of 3D Printing TPU

The knee brace case is just one example of how 3D printing TPU can revolutionize design and manufacturing. Flexible 3D printing materials enable the creation of lightweight, durable, and comfortable parts, such as:

Sports and protective equipment – orthotics, braces, protective pads.

Industrial components exposed to vibration or impact – dampers, seals, flexible mountings.

Technical parts requiring elasticity and longevity – automotive interiors, tooling, ergonomic solutions.

With Prototek’s support in material analysis, design optimization, and additive manufacturing expertise, projects can progress from prototyping to small-series production.

3D printing TPU with ESTANE® 3D TPU M88A expands design possibilities for engineers and designers across multiple industries.

Expanding Applications of 3D Printing TPU Across Industries

3D printing TPU is revolutionizing product development in multiple sectors, offering flexibility, durability, and precision that traditional manufacturing often cannot match.

- In the automotive industry, TPU enables the creation of vibration‑absorbing mounts, flexible connectors, and impact-resistant components that maintain their shape and performance under extreme conditions. Complex geometries and lightweight designs are easily achievable, improving efficiency and reducing weight without compromising durability.

- In footwear and fashion, 3D printing TPU allows designers to create custom shoe soles, ergonomic insoles, and flexible apparel components with unparalleled comfort and adaptability. Tailored designs can be produced quickly, enabling rapid prototyping and limited series production, while delivering personalized fit and style.

- The healthcare sector also benefits from 3D printing TPU, particularly for patient-specific orthotics, prosthetic liners, and flexible supports. TPU’s combination of elasticity and strength ensures comfortable, durable solutions that conform precisely to individual anatomy. Rapid iteration during design and production reduces time to market and enhances the potential for innovative, patient-focused solutions.

Overall, 3D printing TPU is not just a material, it’s a tool for creating high-performance, flexible, and long-lasting components across automotive, footwear & fashion, and healthcare.

Its versatility empowers engineers, designers, and manufacturers to push the boundaries of additive manufacturing, delivering solutions that were previously impossible with traditional materials.

Conclusion: Why 3D Printing TPU Makes a Difference

Today, 3D printing TPU stands among the most versatile solutions for creating functional, durable components. Combining high-performance materials like ESTANE® 3D TPU M88A with HP Multi Jet Fusion technology, Prototek demonstrates that it’s possible to produce products that merge comfort, strength, and precision.

Whether designing for sports, medical, automotive, or industrial applications, 3D printing TPU offers a flexible, reliable, and innovative manufacturing path.

Contact us to request technical datasheets, explore other case studies, and see how 3D printing TPU can elevate your projects.