UMA 90

UMA 90

Resin for Prototypes - Carbon DLS

UMA 90 Resin for Prototypes — Rigid, Affordable, and Fast (Carbon DLS)

UMA 90 Carbon DLS: If you’re looking for a rigid and cost-effective resin for 3D printed prototypes, this is an excellent choice for rapid design validation and functional testing.

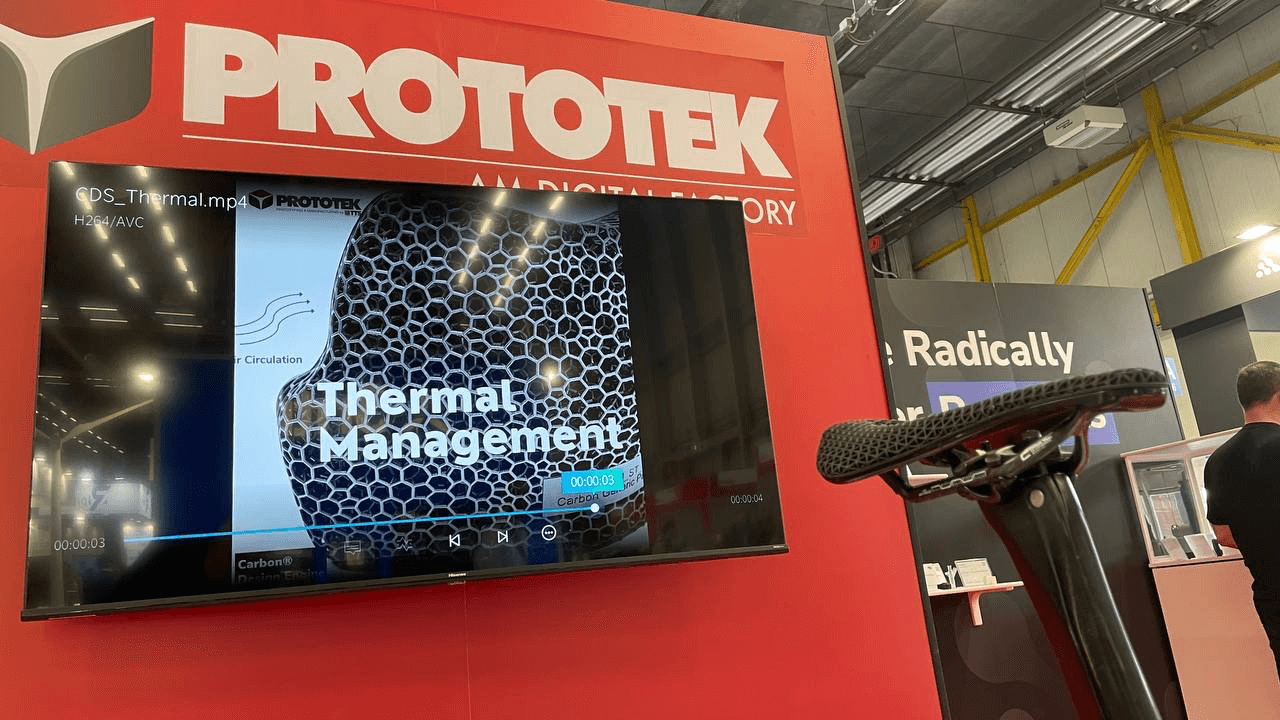

This single-component resin is specifically designed for rapid prototyping using Carbon’s Digital Light Synthesis (DLS) technology, combining high printing speed, ease of use, and a smooth surface finish.

UMA 90 is ideal for jigs, fixtures, visual models, and low-stress parts, where performance, speed, and cost efficiency matter most.

What Is UMA 90?

UMA 90 (Urethane Methacrylate) is a rigid, one-part photopolymer resin developed by Carbon for the DLS 3D printing platform. It delivers consistent quality for visual and functional prototypes that don’t require high mechanical performance but demand excellent surface finish and dimensional accuracy.

Available in a white base color, UMA 90 can also be custom-tinted in shades such as black, gray, cyan, magenta, or yellow—or mixed to match your preferred tone. This flexibility makes it perfect for teams needing aesthetic prototypes that closely resemble final parts before moving to production materials.

Key Benefits of UMA 90 Resin

Rigid, single-component resin: simple handling and no need for two-part mixing.

Affordable for rapid prototyping: ideal for design validation without over-engineering costs.

Compatible with Carbon DLS printers: optimized for M-series systems for precision and consistency.

Custom color options: mixable pigments allow a wide range of visual effects.

Fast printing & iteration: it accelerates concept testing, fit checks, and prototype validation.

Excellent surface finish: this resin produces smooth, detailed parts ready for visual evaluation or light use

Key Features

- Naturally white base; can be printed in different colors upon request.

- “Simple” resin (single-component) printed using the Carbon M2 system.

- Cost-effective.

- Suitable for producing prototypes that do not require high performance.

- Good surface finish.

Why Choose a Rigid Resin for Prototyping?

When validating a design, engineers often need stiff, accurate prototypes that simulate real-world behavior.

UMA 90 Carbon DLS provides high rigidity and stability, making it perfect for form-fit-function testing, assembly validation, and ergonomic studies.

Compared to flexible or high-performance engineering resins, UMA 90 offers shorter print times, simpler post-processing, and lower cost per part, without sacrificing quality where it counts.

It’s the ideal solution when you need to:

Verify geometry or assembly tolerances

Test part fitting or mechanical clearances

Evaluate visual appearance before final production

Create fixtures, jigs, or inspection tools for low-load environments

Typical Applications

Design validation prototypes — test form, fit, and function early in development

Visual models — present accurate, high-quality parts to clients or stakeholders

Jigs and fixtures — create functional tools and assembly aids with short lead times

Masks and templates — produce rigid parts for production or finishing operations

Cable clips, housings, or small components — ideal for rapid iteration and visual testing

UMA 90’s fast print times and easy handling make it a great choice for design teams that value speed, simplicity, and repeatability in their prototyping workflow.

UMA 90 vs Other Carbon DLS Resins

Carbon offers a range of DLS materials—from elastomeric EPU series to rigid RPU or FPU grades.

UMA 90 sits at the entry point of the rigid resin family, balancing printability, speed, and affordability.

| Property | UMA 90 | RPU 70 | EPU 41 |

|---|---|---|---|

| Rigidity | High | Medium-High | Low (flexible) |

| Cost | 💰 Low | 💰💰 | 💰💰💰 |

| Surface Finish | Excellent | Good | Moderate |

| Recommended Use | Prototypes, jigs, fixtures | Functional parts | Elastomeric components |

That’s why UMA 90 is often chosen for early-stage design, when the goal is to test shape, fit, and visual quality before moving to stronger or more complex resins.

Technical Highlights (Typical Properties)

- Tensile Modulus: 1400 MPa

- Tensile Strength: 30 MPa

- Elongation at Break: 30 %

- Flexural Modulus: 1200 MPa

- Shore D Hardness: 86

- Density (cured): 1.20 g/cm³

- Heat Deflection Temperature: 45–50 °C

- Notched Izod Impact: 30 J/m

(Values from Carbon UMA 90 technical data sheet; actual results may vary depending on color and post-cure process.)

Choosing UMA 90 with Prototek

At Prototek, we help European companies accelerate product development using the latest Carbon DLS 3D printing technology.

By printing with UMA 90 resin, you can:

Produce rigid prototypes quickly and affordably.

Validate form and fit before committing to production materials.

Access professional DLS printing with expert finishing and quality control.

Shorten your design cycle with local, on-demand manufacturing.

If your project later requires higher strength or heat resistance, our team can guide you toward advanced Carbon resins like RPU 70, FPU 50, or EPU 41, keeping the same design workflow you developed with UMA 90.

Get Expert Advice

Looking for the best resin for your 3D printed prototypes?

Our specialists can help you choose the right Carbon DLS material based on your part geometry, load requirements, and finish goals.

Contact Prototek today to request a consultation or quote for UMA 90 resin printing.