HP MJF (Multi Jet Fusion) 3D Printing

HP MJF

(Multi Jet Fusion)

Advanced Additive Manufacturing with HP MJF

HP MJF (Multi Jet Fusion) 3D Printing is an advanced additive manufacturing technology that produces high-quality, durable, and functional parts. By leveraging a revolutionary fusion process, this technology ensures exceptional precision, speed, and consistency for both prototyping and series production.

The process selectively fuses nylon PA12 powder using ultra-precise print heads that deposit a fusion agent, combined with energy lamps that generate the heat required to solidify the material. This method delivers superior detail resolution, minimal post-processing, and faster build times, making it ideal for industrial-scale production.

At Prototek, we operate four 4210/5210 Multi Jet Fusion units, enabling efficient production of both small prototype runs and full-scale series components.

Advantages of HP MJF 3D Printing

HP’s MJF (Multi Jet Fusion) technology represents a breakthrough in additive manufacturing, offering:

High printing speed: up to 340 voxels per second, significantly faster than competing 3D printing technologies.

Open software architecture: allows seamless integration and flexible workflow.

Exceptional efficiency: prints up to 10 times faster than traditional methods.

Waste reduction: up to 80% less material waste, making it sustainable and cost-effective.

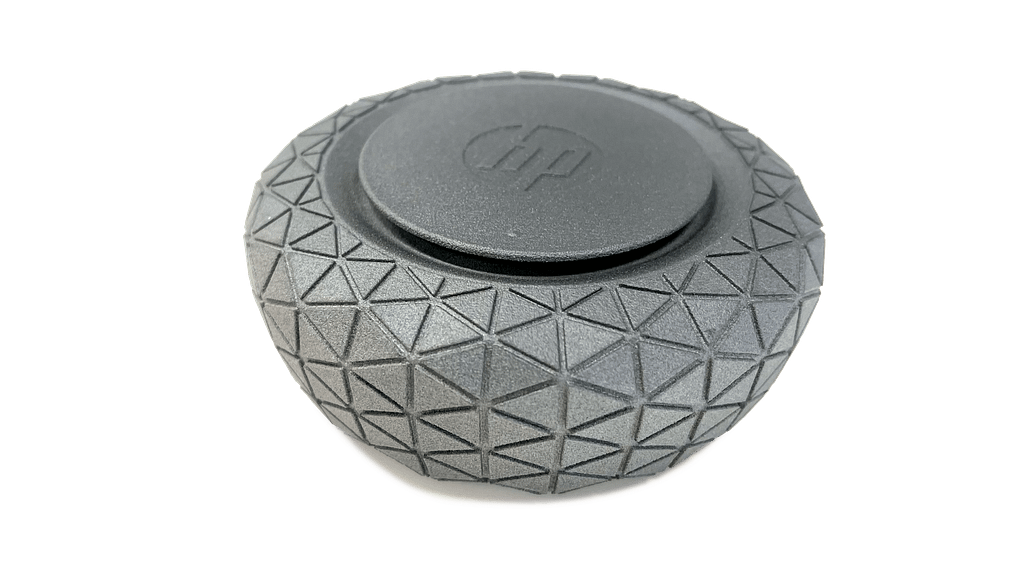

Using fine-grain PA12 material, HP MJF produces ultra-thin layers of just 80 microns, resulting in smooth, uniform surfaces and highly detailed geometries.

The process reduces the need for post-processing and ensures mechanical performance comparable to injection-molded parts, even for complex designs.

Key Features of HP MJF 3D Printing

Material: PA12 (Nylon 12)

High detail and dimensional accuracy: the Multi Jet Fusion process produces precisely defined components, ideal for industrial and engineering applications.

Robustness and durability: PA12 is a high-performance thermoplastic, resistant to wear and suitable for long-lasting, functional parts.

Customizable components: HP MJF enables the production of intricate assemblies, housings, casings, and connectors, even under high mechanical stress, personalizing each part according to the need.

Balanced properties and chemical resistance: PA12 parts exhibit high density, consistent mechanical characteristics, and resistance to oils, greases, and hydrocarbons, making them suitable for harsh environments.

Applications of HP MJF 3D Printing

HP MJF 3D Printing is versatile, supporting a wide range of industrial and commercial applications:

Low-volume production: economical small-batch manufacturing of end-use parts.

Prototypes: functional and form-testing prototypes with mechanical properties comparable to injection-molded parts.

Small components series: cost-effective alternative to traditional injection molding, suitable for connectors, housings, and mechanical assemblies.

Surface Finishing Services by Prototek

To enhance aesthetic quality, Prototek offers a variety of post-processing and finishing options tailored to customer needs.

Micro bead blasting

In addition to the standard treatment, it reduces surface porosity and improves smoothness using a slightly abrasive process.

Impregnation coloring

Uniform black coloring achieved by penetrating the first layers of the part, ensuring stable, long-lasting coloration.

Shiny Black treatment

Combines black impregnation with micro-bead blasting to reduce surface roughness and opacity, resulting in a glossy, scratch-resistant, embossed-like finish.

Trattamento Shiny Black

Graphite treatment

Creates a smooth, anti-scratch, metallic grey surface, one of the highest-quality finishes available.

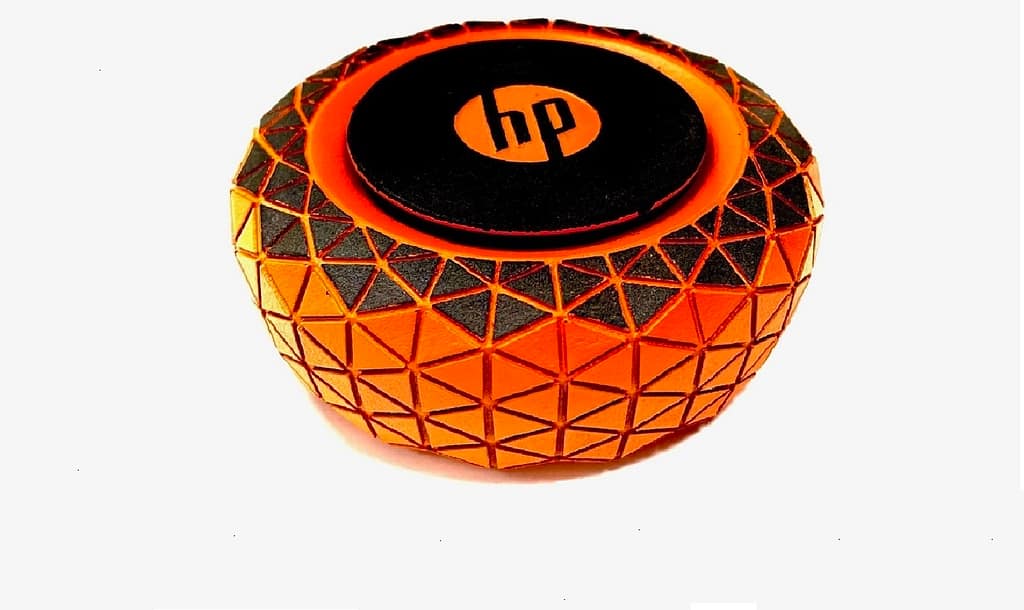

Painting and coatings

Optional professional painting, including surface preparation, to achieve a perfect aesthetic appearance for end-use products.

These services allow clients to obtain parts that are both functional and visually appealing, meeting industrial standards and design specifications.

Why Choose Prototek for HP MJF 3D Printing

Partnering with Prototek means accessing industrial-grade HP MJF 3D printing services, combining:

Precision and high detail

Fast turnaround and scalable production

Superior mechanical performance and surface quality

Customization for functional or aesthetic requirements

Our team evaluates every project to recommend the most suitable materials and finishing processes, ensuring efficient production, reduced lead times, and optimal cost-effectiveness.

Whether for prototypes or full-scale series production, Prototek delivers reliable, high-performance 3D printed parts suitable for mechanical, electronic, consumer, and industrial applications.

Conclusion

HP MJF (Multi Jet Fusion) 3D Printing at Prototek is more than a prototyping tool — it is a complete industrial solution for rapid, precise, and scalable additive manufacturing.

From functional prototypes to series production of complex, high-performance parts, our technology ensures:

Consistent dimensional accuracy

Outstanding mechanical and chemical resistance

Reduced material waste and production costs

Flexible post-processing and finishing options

Discover how HP MJF 3D Printing can enhance your product development, optimize production, and bring your innovative designs to market faster.

Request a consultation with Our Experts