Carbon Design Engine Software

CARBON DESIGN ENGINE

Advanced 3D Lattice Design Software

Carbon Design Engine: Powerful Design Software for High-Performance Products

Carbon Design Engine is a cloud-based lattice design software used by Prototek to develop high-performance products. This innovative platform automates the creation of conformal, multi-zone lattices, allowing designers to avoid repetitive work and focus entirely on product innovation.

Accelerated development: from concept to functional lattice in hours

The cloud-powered computation of this software generates advanced conformal lattices in minutes. Paired with professional 3D printers, it enables a seamless workflow from initial concept to final functional part in just a few hours.

This speed reduces development cycles and accelerates the path to market-ready components.

“Designed for Designers”: save time and eliminate manual tasks

Carbon Design Engine is specifically built for daily designers. Its intuitive interface and powerful algorithms remove the need for tedious manual modeling, leaving room for creativity and engineering optimization. Designers can define density, orientation, and performance parameters for each lattice zone, maintaining full control over the final design.

Proven in

Real-World Production

Carbon Design Software is widely tested and adopted by leading companies to deliver award-winning products.

Integrated into Prototek’s workflow, the platform ensures a rapid, precise, and repeatable transition from digital model to physical part, guaranteeing top-quality results even in the most complex projects.

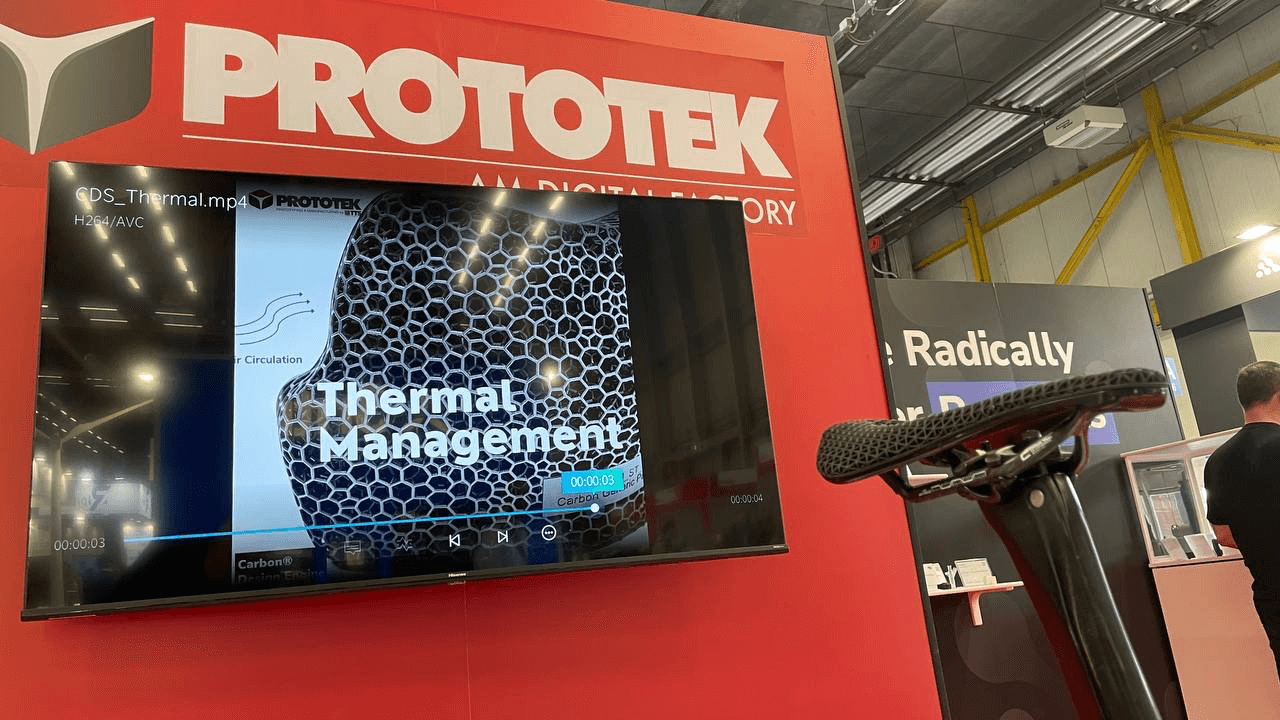

With Carbon Design Engine, multiple performance zones can be defined within a single component and independently optimized.

The software seamlessly merges these zones, creating smooth transitions between areas of varying stiffness or density, resulting in functional, lightweight, and visually appealing lattices.

This approach allows components to be optimized for mechanical, sporting, or medical applications, adapting material properties to meet specific product requirements.

Prototek integrate Carbon Design Engine with Additive Manufacturing Technologies

At Prototek, Carbon Design Engine is fully integrated with advanced additive manufacturing (AM) processes, including Digital Light Synthesis™ (DLS™), and high-performance materials like EPU 41 resin, known for its elasticity and mechanical strength.

This combination of intelligent software and industrial Carbon DLS 3D printing technology produces lightweight yet robust parts, engineered to withstand real-world loads and maintain consistent performance over time.

Continuous Training and Expertise

Through collaboration with Carbon’s Application Engineers, the Prototek team stays updated on software features and best practices for lattice design. From multi-zone configurations to automatic offset mesh generation, every aspect is optimized for maximum efficiency and geometric precision.

This expertise enables Prototek to deliver advanced, customized solutions based on rigorous technical criteria and optimized delivery times.

DLS™ (EPU 41)

Learn from the Application Engineers:

Carbon Design Engine: dashboard and Creating a New Project with Shawn Fortner

Carbon Design Engine: single-Zone Lattice Generation with Kaitlyn Bailey

Carbon Design Engine: setup and Base with Alyson Borrell

Carbon Design Engine: offset mesh with Shawn Fortner

Carbon Design Engine: Multi-Zone Lattice with Alyson Borrell

Carbon Design Engine: advantages with Shawn Fortner

Applications and Success Stories

Lattices designed with this cutting-edge software provide unique performance capabilities, radically improving product behavior.

Notable examples include:

CCM Helmet

Enhanced comfort and impact absorption.

Riddell Helmet

Advanced force distribution and protection.

CellCore GmbH

Structural light-weighting and topological optimization

These case studies illustrate how lattice structures allow mechanical properties to be tailored, maximizing efficiency in terms of weight, stiffness, and durability.

Lattices: The New Frontier of Design

3D lattices represent a new generation of intelligent structural elements. By adjusting mechanical properties at the millimeter level, materials become programmable: rigid where strength is needed, elastic where energy absorption is required, and light where flexibility is essential.

With Carbon Design Engine, Prototek brings this technology to industrial innovation, creating intelligent, high-performance, and customized components.

A Strategic Partner for your next project

Looking to enhance product performance with advanced lattice design?

Prototek’s Carbon lattice design service is ideal for companies, designers, and engineers seeking a combination of quality, speed, and innovation.

From concept to final prototype, our team supports every stage, providing technical assistance, consulting, and tailored production solutions.

Key Features of Carbon Design Engine at Prototek:

Automated creation of complex, multi-zone lattice structures.

Cloud-based computation for rapid development cycles.

Seamless integration with 3D printing technologies like DLS™.

Optimized for mechanical, sporting, and medical applications.

Customizable lattice density, orientation, and performance parameters.

Proven in real-world production for award-winning products.

Lightweight, robust components designed for real-world loads.

Partnering with Prototek and Carbon ensures your product benefits from cutting-edge lattice design, reduced development times, and unmatched precision, taking innovation from idea to reality in record time.